Hydraulic operating table: energy supply for height adjustment in confined spaces

Energy chain, drum and guide trough in operating table solve space and reliability problems.

This mobile operating table is hydraulically operated. Data and electrical cables as well as hydraulic hoses are routed along the column to control and feed the reclining surface. Due to the great height adjustment, they must be reliably guided in the smallest of spaces. After the igus e-chains of the E2/micro product range initially excelled in guiding the electrical cables, the hoses are now also guided in several predefined radii. A guide plate prevents the e-chains from getting caught on the side of the column.

Profile

- What was needed: E2 micro energy chain, designed as a reverse bend radius energy chain, guide trough structure for tilt-free guiding of the chain

- Requirements: small installation space, swerving and tilting of the first energy supply solution in the column of the table due to the high drive forces

- Industry: medicine

- Success for the customer: the design with guide trough and energy chain has proven to be a reliable and trouble-free system in mobile operating tables.

Discover all products for medical technology

Problem

This mobile operating table can be adjusted in height at will and is hydraulically operated. The original aim in developing the table was to be able to control the reclining surface of the operating table in order to lower or raise it.A prototype of the system was to be created at the decommissioning site operated by Sellafield Ltd at a nuclear complex in north-west England. The data and electrical cables should also be planned, including the leading energy chains that run upwards in the table towards the reclining surface. However, several problems became apparent. Due to the enormous height adjustment system, the cable and energy chain had to be considerably long and still be able to fit into a small installation space. During the commissioning of a first solution, it also became apparent that the chain crossbars can tilt in the column due to the drive force exerted on them by a drive wheel.

Solution

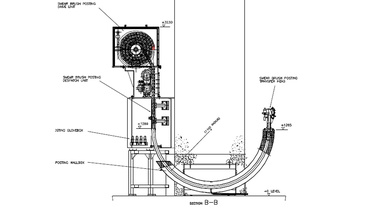

The solution was finally found in an E2 micro energy chain, which is designed as an reverse bend radius energy chain (specification 26.05.125/125), i.e. it has a reverse bend radius. It was chosen because of the solution used in the operating table, which required a long chain that had to fit into a very small space. Today, the chain is wound on a drum in the lower area of the table and is actively unwound by a wheel drive when the reclining surface is raised (push-pull system). However, these drive forces led to the problem of the chain jamming in the column of the table, and because of this a stainless steel guide trough was installed at the lower end of the system. However, the "U-profile" that now guides the chain safely and without tilting is positioned opposite the drum, which necessitated the chain with a reverse bend radius. Once the crossbar strength could be increased by means of the design, the solution proved to be very reliable.