365 days of lubrication-free continuous operation

Dry-operating linear systems in nappy production machines

The output of these highly complex nappy production machines has tripled in recent years without any investment in new machinery. This works on the one hand through very high plant availability, and on the other hand the production process is subject to continuous improvements. In addition, the set-up times have been significantly reduced. Various products from our extensive linear bearing modular system range, which leaves nothing to be desired, provide the necessary flexibility when changing over between the different formats. In the long run, they defy the rough and tumble of everyday operations.Profile

- What was needed: drylin easytube set, RJUM linear plain bearings, lead screw linear units, hybrid bearings from the drylin W product range

- Requirements: High load on the linear technology due to frequent retrofittings with continuous operation almost 365 days a year, high dirt and dust accumulation, contamination due to friction effects

- Industry:

- Success for the customer: Today, drylin linear bearings are used for quick and reliable changeovers. In a wide variety of versions and at a wide variety of locations in the system, they are lubrication-free and maintenance-free, insensitive to dust and dirt, corrosion-free, durable, quiet and lightweight.

Problem

Nappies are produced in what is known as a one-step process. This means that all the required raw materials are in the form of rollers or powders and are assembled into the end product and also packaged in a single process step. The company ONTEX MAYEN GmbH is the market leader in the field of private label hygiene products. It offers a wide range of products for baby, women and adult hygiene. At the Mayen site, a total of eleven plants exclusively produce baby nappies in all sizes and variations, which are sold virtually worldwide.The nappy manufacturer serves many customers. Thus, it must guarantee plant safety and flexibility in production and packaging. Every change of order or size results in changeover times or adjustments. There are typically four size changes per plant per week, which is over 200 size changes per year. However the requirement profile becomes even more complex. Because the plants run around the clock seven days a week. So they are in continuous use almost 365 days a year. Due to the high process speed, the systems are also subject to high dynamic loads. They are as high as 600 m/min.

Due to the process, the ambient temperature in the production hall is rather warm. However, there are no extreme temperatures. Superabsorbents and cellulose are processed, which ensure a relatively high dirt and dust accumulation. Superabsorbent also behaves similarly to sand, so that soiling occurs due to rubbing effects. To sum up, it may be stated that the systems and the machine elements installed in them are subjected to extremely high stresses. Nevertheless, they must function absolutely reliably under all circumstances.

Solution

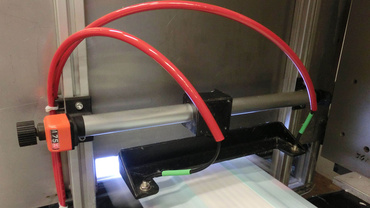

Today, drylin linear bearings are used for quick and reliable changeovers. They are lubrication-free and maintenance-free, insensitive to dust and dirt, corrosion-free, durable, quiet and lightweight.Among other things, the drylin easytube system is used (see pictures 1 - 3 below). The carriages, torque support and trapezoidal lead screw nut of the particularly compact linear unit for easy adjustment tasks are made of a special plain bearing high-performance polymer. This guarantees freedom from lubrication with simultaneously low coefficient of friction and excellent wear rates.

RJUM linear plain bearings replace recirculating ball bearing guides in various areas. They are based on highly wear-resistant polymers, are particularly tough and economical.

But other products are also used in the plants:

Position adjustments

drylin linear bearings primarily implement position adjustments such as in the area of adhesive application points. The adhesive application head is moved reliably by linear guides.

Packaging and visual inspection

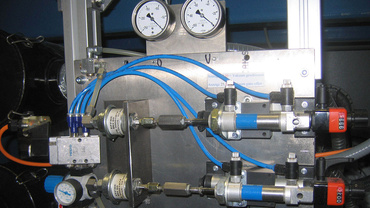

In the packaging environment or in visual inspection and quality assurance, lead screw linear units or systems prove their worth (Pictures 4 - 6). They are often connected with lead screw clamping against unintentional rotation, position indicators for the safe setting of the position and hand wheel.

Material loading cranes

Another special feature of the plants are material loading cranes that bring the heavy raw material rolls to the machine (Picture 7). Hybrid bearings from the drylin W product range have proven themselves in moving the bridge cranes. They offer a combination of sliding and rolling. Coefficients of friction are kept to a minimum, adjustment and drive force are minimised as far as possible.

Thomas Heege, Head of Technology at ONTEX MAYEN GmbH