iglidur plain bearings in ice melting probe withstand glacier conditions

Profile

- What was needed: a reliable storing of the ice screw in inhospitable surroundings

- Manufacturing process: Machined from bar stock

- Requirements: Resistant to water and dirt, thermally insulating

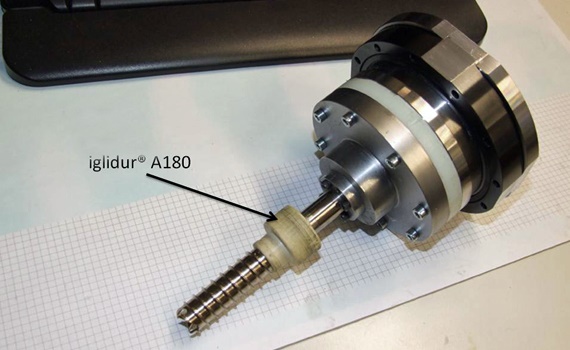

- Material: iglidur A180

- Industry: Research and Development

- Success for the customer: Reliable and resilient bearing for use in extreme conditions

Problem

In this application, plain bearings must function under extreme conditions. In addition to dust and dirt, there are also low temperatures. Furthermore, the installation space is limited and the components come into contact with water during the melting process.Solution

With a specially manufactured plain bearing made of iglidur A180 a media-resistant and robust solution was found. The maintenance-free and lubrication-free operation makes it completely insensitive to dust and dirt. The abrasion-resistant properties also ensure a long service life. The plain bearing was manufactured from iglidur bar stock to perfectly match the application.igus components meet all requirements

The "IceMole" is a melting probe, with which the polar regions, glaciers and as a long-term objective, extraterrestrial regions are to be explored. The probe essentially consists of a heating head with an ice screw and an aluminium housing, in which measuring instruments can be accommodated. The bearing of the ice screw must be insensitive to water and dirt, and should also be thermally insulating. Here, a component machined from an iglidur A180 bar stock has been used.Due to the partial control system of the heaters on the melting head and on the walls of the IceMole, this can melt a path through the ice. Even cornering is possible. During melting, an ice core passes through the hollow ice screw into the interior of the probe, where it can be analysed. With the aid of the ice screw, the probe's melt head is pressed firmly onto the ice, ensuring optimum heat transfer between heating head and ice. In addition, the IceMole can make its way through "dirty" ice and sediment layers with the ice screw.

A media-resistant bearing for small installation spaces was searched for.

The ice screw is located in the middle of the melting head and rotates during the melting process. As a result, it generates tensile force that serves as propulsion for the IceMole.A large moment is generated perpendicular to the axial direction during cornering. To support this, the ice screw bearing is located at the front of the melting head. The bearing should therefore be insensitive to water and dirt.

To effectively melt ice, the gap between the ice screw and the melt head must be small. This limits the installation space for the bearing.

It is important that the ice screw is thermally insulated from the melt head, so that the ice core inside the probe does not melt during the melting process.