Test objects placed in the right light

drylin® linear axes in high-speed inspection installations

Visual inspection of very large numbers of small components: Gefra GmbH in Friedewald, Westerwald, has dedicated itself to the automation of this highly complicated task – something that it does successfully all over the world. For electrical adjustment of the lighting units, Gefra uses complete linear drive units from the drylin® product range of igus.

How can 900 screws or 700 injection-moulded parts be checked for damage per minute? The right answer to this question is supplied by Gefra GmbH. Established in 1995, the company specialises in the development of automated installations for fast and precise visual inspection and measurement of components.

The realisation that there was a need here was the reason why the company was established. Dipl.- Thomas Rothweiler, founder and managing partner of the company, used to advise manufacturers on rationalisation and automation. When doing so, he found that, at the end of highly automated processes, checking was often still being done with the human eye and parts were being sorted manually.

Visual inspection of very large numbers of small components: Gefra GmbH in Friedewald, Westerwald, has dedicated itself to the automation of this highly complicated task – something that it does successfully all over the world. For electrical adjustment of the lighting units, Gefra uses complete linear drive units from the drylin® product range of igus.

How can 900 screws or 700 injection-moulded parts be checked for damage per minute? The right answer to this question is supplied by Gefra GmbH. Established in 1995, the company specialises in the development of automated installations for fast and precise visual inspection and measurement of components.

The realisation that there was a need here was the reason why the company was established. Dipl.- Thomas Rothweiler, founder and managing partner of the company, used to advise manufacturers on rationalisation and automation. When doing so, he found that, at the end of highly automated processes, checking was often still being done with the human eye and parts were being sorted manually.

Automated high-speed inspection

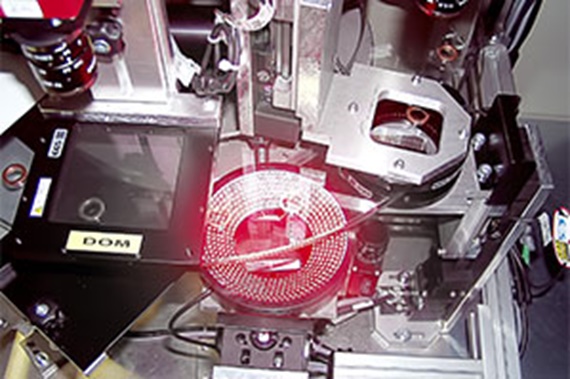

The Optisort machines that he then developed use camera technology combined with automated infeed equipment and extremely fast computing systems. Seeing the speed of such an installation in action is impressive: Coming out of a bunker system and transported by a push-bar conveyor, the test objects are fed into the system individually and, if necessary, in the right position. Resting either on a glass plate, a special metal plate for screws or a conveyor belt, they are taken past a series of cameras. 360° inspections with four cameras are also possible. Good parts are actively discharged, defective parts are separated out.

All this happens at a speed that the human eye can hardly keep up with. "The installations inspect several hundred parts per minutes, and sometimes more than 50,000 per hour“, says Thomas Rothweiler. At the same time, they are also very flexible as they can inspect different components: "Each machine typically inspects 200 to 300 products. " There is a special inspection programme for each particular product.

The Optisort machines that he then developed use camera technology combined with automated infeed equipment and extremely fast computing systems. Seeing the speed of such an installation in action is impressive: Coming out of a bunker system and transported by a push-bar conveyor, the test objects are fed into the system individually and, if necessary, in the right position. Resting either on a glass plate, a special metal plate for screws or a conveyor belt, they are taken past a series of cameras. 360° inspections with four cameras are also possible. Good parts are actively discharged, defective parts are separated out.

All this happens at a speed that the human eye can hardly keep up with. "The installations inspect several hundred parts per minutes, and sometimes more than 50,000 per hour“, says Thomas Rothweiler. At the same time, they are also very flexible as they can inspect different components: "Each machine typically inspects 200 to 300 products. " There is a special inspection programme for each particular product.

Mechanical considerations and computing speed impose technical limits.

In the past, in the course of ongoing improvement of the machines, the mechanics of the system continually came up against its limits with regard to the high speed at which components were fed into the installation. Sometimes, however, the computing speed of the available control units also reached a limit, a fact which is not surprising given that, in some cases, eight or ten cameras inspect the test object and the control system has to make a decision within milliseconds as to whether the parts are "OK" or "NOK".

In the past, in the course of ongoing improvement of the machines, the mechanics of the system continually came up against its limits with regard to the high speed at which components were fed into the installation. Sometimes, however, the computing speed of the available control units also reached a limit, a fact which is not surprising given that, in some cases, eight or ten cameras inspect the test object and the control system has to make a decision within milliseconds as to whether the parts are "OK" or "NOK".

Electrical adjustment of the lighting

Even though each machine is individually adapted to the customer's wishes, Thomas Rothweiler emphasises that the machines are by no means special constructions: "Our machines are based on a modular principle and we use very many identical parts. “

A current new feature concerns the lighting, whereby the test objects are placed in the right light for the cameras. The distance between the lights and the test object varies, depending on the product, and the user adjusts the lights manually by means of an adjusting wheel with a scale. The aim of Thomas Rothweiler was to integrate this into the control system and thus make it reproducible. In this way, the intention was not just to cut back on the number of manual steps in the process and rule out possible incorrect positioning of the test objects. It was even more important to integrate the positioning of the lights into the documentation.

Even though each machine is individually adapted to the customer's wishes, Thomas Rothweiler emphasises that the machines are by no means special constructions: "Our machines are based on a modular principle and we use very many identical parts. “

A current new feature concerns the lighting, whereby the test objects are placed in the right light for the cameras. The distance between the lights and the test object varies, depending on the product, and the user adjusts the lights manually by means of an adjusting wheel with a scale. The aim of Thomas Rothweiler was to integrate this into the control system and thus make it reproducible. In this way, the intention was not just to cut back on the number of manual steps in the process and rule out possible incorrect positioning of the test objects. It was even more important to integrate the positioning of the lights into the documentation.

Complete linear drive unit as a solution

When searching for suitable linear drives, the Gefra engineers found what they wanted in the drylin® product range from igus®. On the basis of drylin® linear axes, whereby a carriage made of the high-performance polymer iglidur® is moved with the help of a lead screw drive, igus® developed the drylin® E product range. (E for electric). These are complete linear drive motors, whereby a stepper motor drives the axis via an optional flange and a claw coupling, which is also optional.

With this axis, Gefra creates the preconditions for integrating the light-adjustment system into the PC control unit and thus into the respective inspection plan and for taking the process of automation one step further. An axis with a 60 mm stroke is used; it is driven by a NEMA 17 stepper motor and moves loads of up to 1000 g with a precision of +/- 0.5 mm.

When searching for suitable linear drives, the Gefra engineers found what they wanted in the drylin® product range from igus®. On the basis of drylin® linear axes, whereby a carriage made of the high-performance polymer iglidur® is moved with the help of a lead screw drive, igus® developed the drylin® E product range. (E for electric). These are complete linear drive motors, whereby a stepper motor drives the axis via an optional flange and a claw coupling, which is also optional.

With this axis, Gefra creates the preconditions for integrating the light-adjustment system into the PC control unit and thus into the respective inspection plan and for taking the process of automation one step further. An axis with a 60 mm stroke is used; it is driven by a NEMA 17 stepper motor and moves loads of up to 1000 g with a precision of +/- 0.5 mm.

Lubricant-free operation

One crucial criterion when the choice was being made was the lubricant-free operation of lead screw and carriages: As the light units in the working space of the installation are directly above, next to and below the objects to be inspected, it must be ensured that the drives do not give out any foreign substances that could impair the inspection process.

The compact design of the drive units was equally important. Thomas Rothweiler: "As we will be offering electric adjustment as an option in future, it must also be possible to integrate it into the existing technical design. It is also important for us that we obtain the entire unit, including motor, carriages and fastenings, from a single source and ready for installation. “

One crucial criterion when the choice was being made was the lubricant-free operation of lead screw and carriages: As the light units in the working space of the installation are directly above, next to and below the objects to be inspected, it must be ensured that the drives do not give out any foreign substances that could impair the inspection process.

The compact design of the drive units was equally important. Thomas Rothweiler: "As we will be offering electric adjustment as an option in future, it must also be possible to integrate it into the existing technical design. It is also important for us that we obtain the entire unit, including motor, carriages and fastenings, from a single source and ready for installation. “

Optisort at igus® as well

The new concept has already been tried out in a machine that inspects seals. Four lead screw linear tables of the type drylin SAW-0630 with electric drive, motor flange and integrated claw coupling are connected to the PC of the system via controllers. The drives fit into this environment very well.

By the way, the advantages of Optisort installations are very much appreciated at igus®. The reason is that four machines from Gefra inspect bearings in the Cologne production facility. This primarily concerns safety-relevant components that igus makes for the automotive industry and have to be checked 100 per cent. At the moment, igus® is planning to acquire a fifth Optisort machine. If the persons responsible choose the electric light-adjustment option, some of the drylin E units delivered to Friedewald will come back to the place where they were produced.

The new concept has already been tried out in a machine that inspects seals. Four lead screw linear tables of the type drylin SAW-0630 with electric drive, motor flange and integrated claw coupling are connected to the PC of the system via controllers. The drives fit into this environment very well.

By the way, the advantages of Optisort installations are very much appreciated at igus®. The reason is that four machines from Gefra inspect bearings in the Cologne production facility. This primarily concerns safety-relevant components that igus makes for the automotive industry and have to be checked 100 per cent. At the moment, igus® is planning to acquire a fifth Optisort machine. If the persons responsible choose the electric light-adjustment option, some of the drylin E units delivered to Friedewald will come back to the place where they were produced.