User report

Durable, maintenance-free plain bearings and linear bearings for production machines

The example of Wöhler Brush Tech GmbH brush production machines

When there is movement in production, there are also countless bearings such as plain and linear bearings in the machines. Designers' goals are usually the same: bearings with high running performance, low wear, high load capacity, and easy maintenance.Wöhler Brush Tech, a world-famous manufacturer of brush production machines, shows how the various bearing points in its machines are equipped with iglidur and drylin plain and linear bearings. and the advantages that result.

Profile

- What was needed: iglidur J plain bearings, iglidur G plain bearings, RJM/RJMP-series plain bearing bushings, drylin T-series linear plain bearings, drylin SLWE-PL-series lead screw module, drylin W-1660

- Requirements: The high production speed with short, dynamic strokes required durable materials and bearings with good coefficients of wear. Hair and dust in the system meant that a lubrication-free solution was needed.

- Industry: Mechanical engineering

- Success for the customer: Wöhler Brush Tech GmbH purchases various types of iglidur material for linear and plain bearings. The specialist benefits from bearing operation that requires no lubrication or maintenance. The optimised coefficients of friction for bearings with incorporated lubricant allow long service life.

Discover all products for machine tools

Wöhler Brush Tech GmbH machines – proven worldwide.

Regardless of size and brush and fill type, many manufacturers of technical brushes worldwide use machines from Wöhler Brush Tech GmbH. There are good reasons for this: Wöhler has been active in the brush industry for more than 75 years. The company offers a comprehensive range of systems for manual or automated brush production, covering the entire process chain, starting with injection moulding (for the body and fixing elements) and extrusion (for the bristles). The modular design allows the machines to be individually adapted to individual customer requirements.Machines with high demands on bearing points

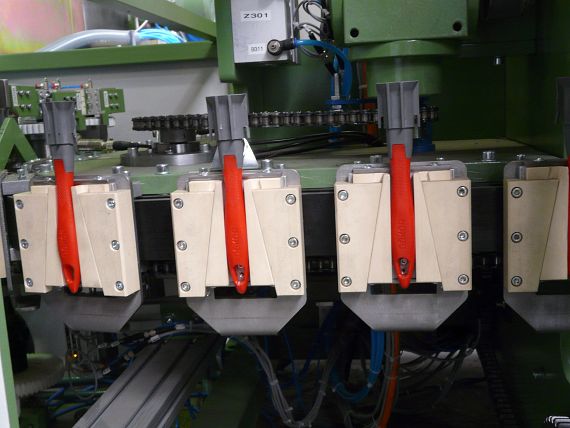

If the customer so wishes, Wöhler Brush Tech GmbH production machines also allow high production speeds: With a system that produces 60 flat brushes per minute, Wöhler holds the unofficial world record for brush production performance. Those who see such a machine in operation notice two things: First, brush manufacture requires a number of coordinated movements, many of which are very dynamic with short strokes. During bearing selection for these movements, not only robust, but also durable materials were required. Second, hair and dust from the cut bristles also clog the bearing points. A whole machine work step is devoted to trimming and smoothing the bristles. With lubricant, the bristles tend to adhere. The intensive search for a durable solution free of maintenance and lubrication began.

The solution: iglidur plain bearings and drylin linear bearings

The Wöhler designers made a fundamental decision for their machines: Today they use iglidur plain bearings and drylin linear bearings made of high-performance polymers for many different rotary and linear bearing support solutions.For the bearing series materials, Wöhler uses iglidur J and, even more frequently, the "all-rounder", iglidur G (more about iglidur materials here). The material works well universally with medium to high loads, medium surface speeds, and medium temperatures. Wöhler tends to use iglidur J for linear bearings and iglidur G for rotating and pivoting movements.

Despite the dust, both plain and linear bearings are maintenance-free, and no preventive maintenance is necessary. The reason is the bearing materials, whose operation is completely dry, requiring no addition of external lubricants. If there is no lubrication, the dust from cutting and smoothing the bristles cannot adhere, the bearing points do not clog, and the dust can simply be vacuumed off.

Overview of iglidur® plain bearings

Durable, wear-optimised, and easy to install

The optimised coefficients of friction for high-performance polymer bearings with incorporated lubricant allow long service life. This is so pronounced that Wöhler sometimes dismantles other types of bearings from purchased drive axes and replaces them with iglidur bearing bushes or drylin linear bearings.Should bearing service life nevertheless end at some point, the bearing wear does not lead to immediate failure. Instead, an increased clearance gradually becomes noticeable. Sudden production stops are eliminated, and bearing replacement can be effectively planned.

The customer also emphasizes that the mono-material bearings are easier to install than plain bearings made of multi-layer material.

Bar stock also proves itself in practice.

In addition to iglidur and drylin bearing products, Wöhler Brush Tech GmbH also uses bar stock. On the FP 900 B machine, for example, 40 handles for flat brushes are clamped on a central rotary table. The grippers used here are made of iglidur J bar stock, which Wöhler processes in-house. The grippers are therefore simply constructed and extremely durable: They need neither ball bearings nor cam rollers.Wöhler also often uses bar stock in the customer service area. For example, Wöhler converted the existing drive systems of a customer's machine with this technique. A toothed belt drive with recirculating ball bearing guides was used in the filament production. Wöhler suggested to its customer that the drive be guided with linear bearings made from iglidur J, milled from bar stock. The result is convincing: In a machine that is already in use, the axes have already covered 8,000km after just 55 days – without any signs of wear.

iglidur bar stock overview

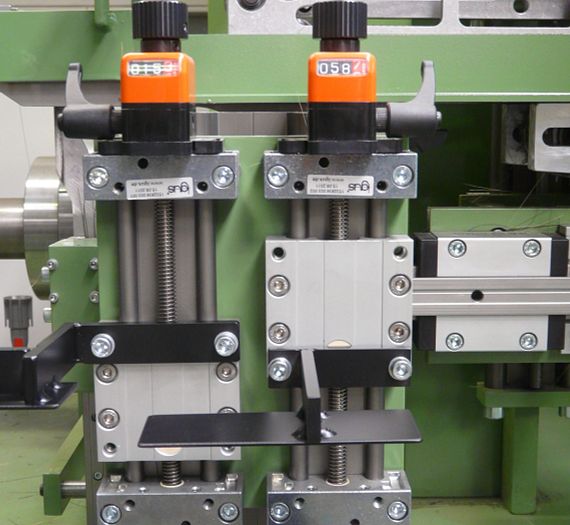

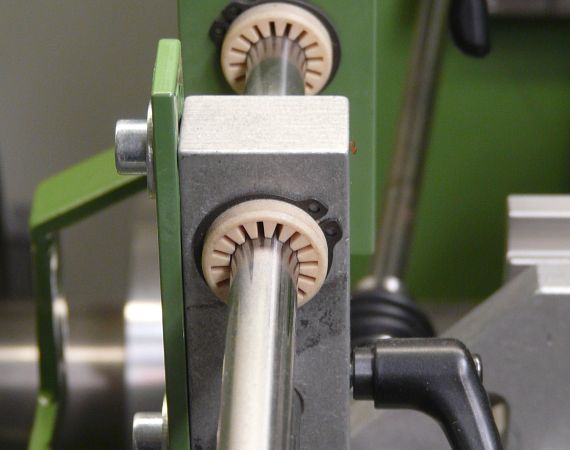

Linear bearings and linear systems in format adjustment

At many FP 900 B flat brush machine bearing points, Wöhler often uses RJM/RJMP-series linear plain bearing bushings to guide cylinders. To adjust format for several axes, drylin T linear plain bearings have proven effective. In one case – smoothing the brush after glue is applied – relatively high forces and a clearance-free format adjustment is needed. Here, the Wöhler design engineers use a drylin SLWE-PL-series lead screw module to ensure high rigidity for a shaft diameter of 16mm. The drylin W-1660 double rail guide is also used in Wöhler Brush Tech brush machines.The online shop has also benefited the manufacturer, who was able to draw on a wide range of products for his machines. There, part numbers can be called up individually with prices, all bearing series calculated, and CAD data downloaded. This saves valuable design time.

Overview of drylin linear guides