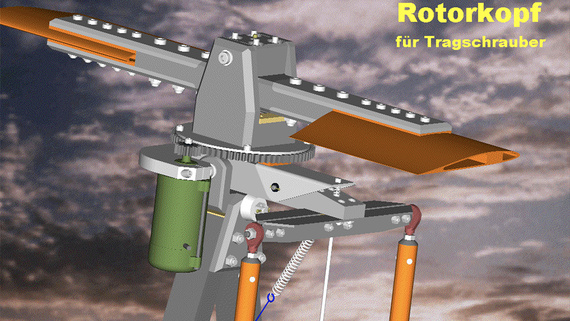

Lightweight and maintenance-free pillow block bearings in the rotor head for ultralight gyrocopters

Reliable and vibration-dampening: iglidur plain bearings and igubal pillow block bearings in the rotor head

manus® 2007

iglidur® G è la soluzione per questa testa rotore Le pale del rotore ruotano a 400 giri al minuto ed eseguono un movimento oscillante con un angolo massimo di 30°. La struttura è composta da due cuscinetti in tecnopolimero e due rondelle reggispinta in iglidur® G.La testa del rotore è controllabile mediante asse longitudinale e trasversale, tuttavia raramente si verificano movimenti di regolazione. Quattro cuscinetti e rondelle reggispinta sono montati sulla testa. Altri cuscinetti assorbono il movimento rotatorio della leva del freno. Inoltre sono stati aggiunti due supporti snodati a omega igubal® per lo sterzo in grado di smorzare le vibrazioni e compensare i disallineamenti.

Per tutti i prodotti igus® utilizzati, il criterio principale di utilizzo è il peso ridotto e l'assenza di manutenzione.

Walter Schwarz, Schwarz Industrieservice, Schwabach

Profile

- What was needed: iglidur plain bearings, igubal pillow block bearings

- Requirements: A lightweight and reliable bearing for the rotor head and brake lever was sought.

- Industry: Aerospace, aviation industry

- Success for the customer: The decision for the bearings resulted from several reasons: They are particularly vibration-dampening, insensitive to dust, low-maintenance, compact and especially light. In addition, they have high strength values and convinced the customer with their low cost.

Problem

For this ultra-light gyroplane, Schwarz Industrieservice was looking for a suitable bearing for the rotor head. The rotor blades rotate dynamically at approx. 400 revolutions per minute, performing oscillating movements of max. 30°. A grease lubrication device is provided for this purpose. The gimballed rotor head can be steered around the longitudinal and transverse axis. Only occasional steering movements occur in the process. An initial filling with grease is sufficient. A rotor brake must brake the rotor speed from approx. 200 revolutions per minute to standstill. The rotary movement of the brake lever also had to be supported.Solution

For the bearing of the longitudinal and transverse axis of the rotor head, four plain bearings and thrust washers made of the material iglidur G were chosen. Two iglidur plain bearings were also used for the rotary movement of the brake lever for the rotor brake. The braking torque is absorbed by two iglidur thrust washers. For the control of the rotor head, two igubal pillow block bearings are used, which are vibration-dampening and compensate for misalignments.The decision for the bearings resulted from several reasons. It is particularly vibration-dampening, insensitive to dust, low-maintenance, compact and especially light. In addition, they have high strength values. Finally, the cost-effective prices were also convincing for the choice of the iglidur G plain bearings.