Exclusive preview

Produce, fill, label: Lubrication-free bearings in a PET filling plant

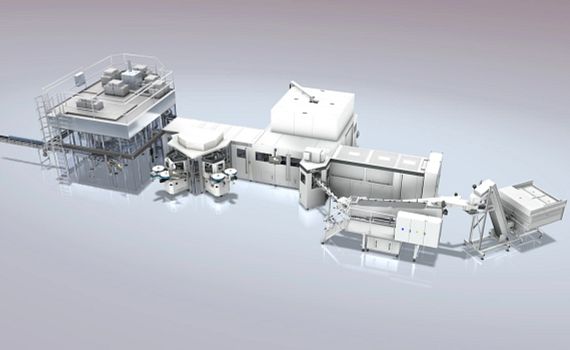

Compact "InnoPET TriBlock bottling system" from KHS works with our plain bearings, linear bearings, ball bearings and linear systems

Buy the completely finished bottling plant as a single, compact system. KHS makes this possible with the InnoPET TriBlock. This is convenient and saves space for customers. From the production of PET bottles to filling and labelling, everything has been thought of. However, since a large number of moving parts are also used in all process steps, KHS uses our lubrication-free plain, linear and ball bearings as well as lead screw linear systems at many points in the plant - for continuous operation and continuous temperatures of 50°C.Profile

- What was needed: iglidur J plain bearings; drylin R liners; xiros ball bearings; drylin SLW type linear system; drylin linear guides

- Requirements: Lubrication-free, wear resistance, long-lasting operation in continuous use and at temperatures of approx. 50°C

- Industry: Beverage bottling plants

- Success for the customer: The self-lubricating plain bearings, ball bearings and liners easily withstand the environmental conditions in the system. The wide range of materials and special parts for the system also contribute to this.

Problem

Produce, label and fill PET bottles ... with just one machine. The InnoPET TriBlock from KHS enables this and thus offers customers two specific advantages: It is complete and does not have to be integrated into existing systems and is also very compact.It is not surprising that there is a lot of movement on such machines. Plain, linear and ball bearings as well as linear axes and rollers must be used in the gripping unit of the bottles, and for deflection in the labelling system, or for adjusting the format of an entire process block.

The choice of these products is crucial, as they can significantly influence the customer's machine availability and service life at a later stage. When it comes to sensitive filling, the focus is on the freedom of lubricating grease of the moving components. For this purpose, all products must be wear-resistant and have a long service life. And all this with continuous operation and temperatures of approx. 50°C.

Solution

The InnoPET TriBlock works with a whole range of our "motion plastics" from different product ranges.For example, when it comes to bottle holders, which must be mounted safely and, above all, lubrication-free. Various iglidur J plain bearings for guiding the springs are accompanied by drylin R liners (JUMO-01-20) for the stroke movement to clamp the bottles.

Plastic rollers specially manufactured for this purpose also safely initiate the linear stroke.

In the labelling process, the carbon tubes, which pass up to 82,000 labels per hour with the aid of pressed-in xiros ball bearings are immediately noticeable.The built-in linear adjustment of the entire labelling block is also particularly exciting. The 600kg unit is powered by a specially manufactured drylin SLW-1660 type linear lead screw system and two WSQ-16 type drylin guides at the rear operated safely, maintenance-free and lubrication-free.