Cambia lingua :

Cuscinetti a strisciamento iglidur® nei test oscillatori di confronto rispetto ai cuscinetti a rullini

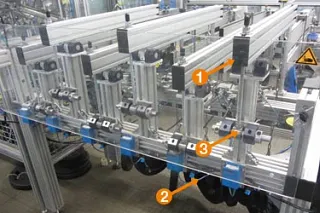

Per effettuare una serie di test nel laboratorio igus®, il cliente ha fornito gli alberi utilizzati nell'applicazione. I test sono stati condotti nel laboratorio di prova in loco con una macchina di prova standard (immagine 1). Nell'applicazione del cliente, è possibile in parte un elevato ingresso di sporco. Pertanto, la lubrificazione non è desiderata e, inoltre, la lubrificazione necessaria per i cuscinetti ad aghi può essere garantita solo entro limiti per l'intero tempo di funzionamento. Pertanto, i cuscinetti a strisciamento sono stati testati in condizioni di normale funzionamento, ovvero a secco senza lubrificazione, e i cuscinetti ad aghi con e senza lubrificazione. Nella prima fase, tutti i test sono stati eseguiti senza ingresso di sporco. Con i cuscinetti a strisciamento iglidur®, l'usura è stata determinata tramite la variazione del diametro interno nella direzione del carico. Per questo, il diametro interno è stato misurato con un micrometro esterno prima e dopo i test. La differenza è l'usura. Per mezzo della frequenza del ciclo, è stata determinata la prestazione di funzionamento per confrontare l'usura. Il diametro interno dei cuscinetti ad aghi non poteva essere misurato con i mezzi forniti in laboratorio. Qui l'usura è stata determinata tramite la perdita di massa.

Immagine 1: I test sono stati condotti nel laboratorio di prova in loco con una macchina di prova standard

1

Leva per la trasmissione di potenza

2

Carico

3 Punto di prova

Il test di usura è stato eseguito con i seguenti parametri: Parametro valore cuscinetto iglidur® P210 iglidur® Q iglidur® Q2 Cuscinetto a rullini Cuscinetto a rullini albero Albero cliente (nitrurato) Albero cliente (nitrurato) Albero cliente (nitrurato) Albero cliente (nitrurato) Albero cliente (nitrurato) carico 4 MPa 4 MPa 4 MPa 4 MPa 4 MPa Tipo di movimento Orientabile Orientabile Orientabile Orientabile Perno Angolo di orientamento 60° 60° 60° 60° 60° velocità 0,01 m/s 0,01 m/s 0,01 m/s 0,01 m/s 0,01 m/s lubrificazione no no no no OKS 400 (una tantum) Numero di cicli target 600000 600000 600000 600000 600000

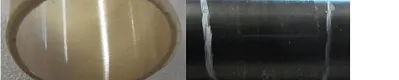

Figura 2: cuscinetto iglidur® P210 testato senza lubrificazione con albero associato

Figura 3: cuscinetto iglidur® Q testato senza lubrificazione con albero associato

Figura 4: cuscinetto iglidur® Q2 testato senza lubrificazione con albero associato

Figura 5: Cuscinetto a rulli ad aghi testato senza lubrificazione con albero associato

Confronto

dell'usura media iglidur® P210, iglidur® Q, iglidur® Q2; p=4MPa; v=0,01 m/s; angolo di inclinazione 60°

Risultato:

i cuscinetti a rullini non lubrificati si sono rotti dopo circa 1/10 - 1/3 del tempo di funzionamento nominale. Anche l'albero è stato gravemente danneggiato. I cuscinetti a rullini lubrificati sono diventati più pesanti. Ciò è probabilmente dovuto al grasso che si è depositato nel cuscinetto e ha legato abrasione e sporcizia. Tuttavia, sembra che ci sia stata solo pochissima usura sul cuscinetto. Tutti i cuscinetti iglidur® hanno raggiunto la loro durata di servizio target e sono ancora completamente funzionali, proprio come i cuscinetti a rullini lubrificati. Anche gli alberi mostrano solo lievi segni di usura. I cuscinetti a strisciamento realizzati in iglidur® P210 hanno ottenuto i migliori risultati di usura e anche il modello di funzionamento sugli alberi sembra migliore in combinazione con i cuscinetti a strisciamento iglidur® P210. Sulla base di questi risultati, la raccomandazione per un cuscinetto non lubrificato nell'applicazione è un cuscinetto a strisciamento realizzato nel materiale iglidur® P210. Ulteriori test con ingresso di sporcizia possono essere eseguiti anche nella fase successiva, se necessario.

Consulenza

A tua disposizione per rispondere a dubbi e domande

igus® s.r.l.+39 039 59061Scrivimi!

Spedizioni e consulenza

Personale:

Dal lunedì al venerdì dalle 8:00 alle 18:00.

Sabato dalle 8:00 alle 12:00.

Online:

24h